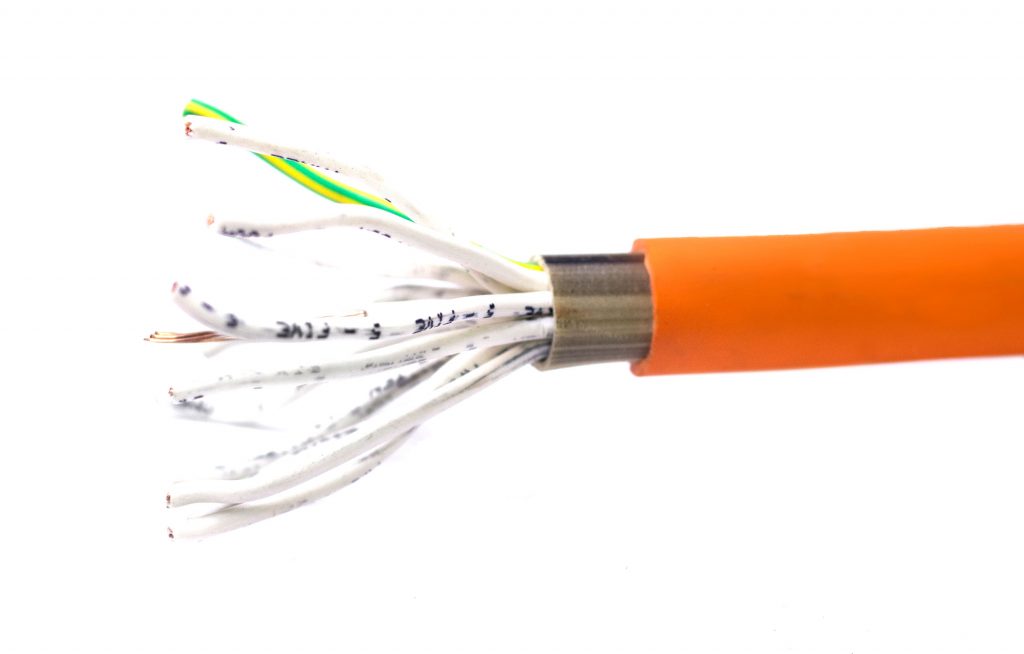

Control cables have several cores for controlling automated processes. These cables can either be screened or unscreened. Screened cables are installed in environments where there is tendency for interferences. The screen component of the cable is a metal tape applied helically with overlaps. The choice of insulation material is made considering the conditions of installation.

We manufacture Control Cables for industrial application, conforming to IEC 60502-1 or other customer specification.

Product Data Tables

| Conductor: | class 1&2 (annealed plain copper) |

| Insulation: | PVC |

| Inner & outer sheath: | PVC |

| Identification of core: | five core - green-yellow, blue, brow, black, grey above 5-core - number printing on white/black insulation, one is green-yellow |

| Nominal cross sectional area of conductor | Thickness of insulation | Thickness of inner sheath | Thickness of outer sheath | Approximate overall diameter |

| mm2 | mm | mm | mm | mm |

| 7 x 1.5 | 0.8 | 1.0 | 1.8 | 18.1 |

| 8 x 1.5 | 0.8 | 1.0 | 1.8 | 19.5 |

| 9 x 1.5 | 0.8 | 1.0 | 1.8 | 20.6 |

| 11 x 1.5 | 0.8 | 1.0 | 1.8 | 21.7 |

| 12 x 1.5 | 0.8 | 1.0 | 1.8 | 21.7 |

| 13 x 1.5 | 0.8 | 1.0 | 1.8 | 22.2 |

| 16 x 1.5 | 0.8 | 1.0 | 1.8 | 23.5 |

| 18 x 1.5 | 0.8 | 1.0 | 1.8 | 24.4 |

| 19 x 1.5 | 0.8 | 1.0 | 1.8 | 24.4 |

| 21 x 1.5 | 0.8 | 1.0 | 1.8 | 25.5 |

| 31 x 1.5 | 0.8 | 1.0 | 1.8 | 29.5 |

| 41 x 1.5 | 0.8 | 1.0 | 1.9 | 33.1 |

| 48 x 1.5 | 0.8 | 1.2 | 2.0 | 35.2 |

| 7 x 2.5 | 0.8 | 1.0 | 1.8 | 19.4 |

| 12 x 2.5 | 0.8 | 1.0 | 1.8 | 23.6 |

| 13 x 2.5 | 0.8 | 1.0 | 1.8 | 24.1 |

| 19 x 2.5 | 0.8 | 1.0 | 1.8 | 26.7 |

| 61 x 2.5 | 0.8 | 1.2 | 2.2 | 42.3 |

| 6 x 4 | 1.0 | 1.0 | 1.8 | 23.3 |

| 7 x 4 | 1.0 | 1.0 | 1.8 | 23.3 |

| 12 x 4 | 1.0 | 1.0 | 1.8 | 27.5 |

| 14 x 4 | 1.0 | 1.0 | 1.8 | 28.7 |

| 16 x 4 | 1.0 | 1.0 | 1.8 | 30.0 |

| 19 x 4 | 1.0 | 1.0 | 1.9 | 31.6 |

| 24 x 4 | 1.0 | 1.2 | 2.0 | 36.7 |

| 30 x 4 | 1.0 | 1.2 | 2.1 | 38.8 |

| 37 x 4 | 1.0 | 1.2 | 2.2 | 41.7 |

| 6 x 6 | 1.0 | 1.0 | 1.8 | 24.0 |

IEC 60502-1

|

Conductor. |

Class 2 (annealed plain copper/ aluminium) |

|

Insulation: |

XLPE |

|

Inner & outer sheath: |

PVC |

|

Identification of core: |

4-core: red, yellow, blue, black 6, 7, 12, 19 – core: black with number tags |

|

Number of cores x cross sectional area of conductor |

Thickness of insulation |

Thickness of inner sheath |

Cu screen thickness |

Thickness of outer sheath |

Approximate overall diameter |

|

mm2 |

mm |

mm |

mm |

mm |

mm |

|

7x2.5 |

0.7 |

1.0 |

0.10 |

1.8 |

26.1 |

|

12x2.5 |

0.7 |

1.0 |

0.10 |

1.8 |

30.1 |

|

19x2.5 |

0.7 |

1.0 |

0.10 |

1.8 |

32.9 |

|

4x4 |

0.7 |

1.0 |

0.10 |

1.8 |

25.4 |

|

6x4 |

0.7 |

1.0 |

0.10 |

1.8 |

27.7 |

|

4x6 |

0.7 |

1.0 |

0.10 |

1.8 |

26.8 |

|

6x6 |

0.7 |

1.0 |

0.10 |

1.8 |

29.4 |

IEC 60502-1

|

Conductor: |

class 2 (annealed plain copper) |

|

Insulation: |

PVC |

|

Inner & outer sheath: |

PVC |

|

Identification of core: |

numbering printing on white / black insulation, one is green-yellow. |

|

Armouring: |

Aluminium Wire Armour (AWA) Steel Wire Armour subject to availability |

ARMOURED AUXILIARY CABLES

|

Number of cores cross sectional area of conductor a |

Thickness of insulation |

Thickness of inner sheath |

Nominal AWA diameter |

Thickness of outer sheath |

Approximate overall diameter |

|

No x mm2 |

mm |

mm |

mm |

mm |

mm |

|

7x1.5 |

0.8 |

1.0 |

2.0 |

1.8 |

24.1 |

|

8x1.5 |

0.8 |

1.0 |

2.0 |

1.8 |

25.5 |

|

9x1.5 |

0.8 |

1.0 |

2.0 |

1.8 |

26.6 |

|

11x1.5 |

0.8 |

1.0 |

2.0 |

1.8 |

27.2 |

|

12x1.5 |

0.8 |

1.0 |

2.0 |

1.8 |

27.7 |

|

13x1.5 |

0.8 |

1.0 |

2.0 |

1.8 |

28.5 |

|

14x1.5 |

0.8 |

1.0 |

2.0 |

1.8 |

28.5 |

|

16x1.5 |

0.8 |

1.0 |

2.0 |

1.8 |

29.5 |

|

18x1.5 |

0.8 |

1.0 |

2.0 |

1.8 |

30.4 |

|

19x1.5 |

0.8 |

1.0 |

2.0 |

1.8 |

29.4 |

|

21x1.5 |

0.8 |

1.0 |

2.0 |

1.8 |

31.5 |

|

24x1.5 |

0.8 |

1.0 |

2.0 |

1.9 |

33.8 |

|

27x1.5 |

0.8 |

1.0 |

2.0 |

1.9 |

34.2 |

|

30x1.5 |

0.8 |

1.0 |

2.0 |

1.9 |

35.1 |

|

31x1.5 |

0.8 |

1.0 |

2.0 |

2.0 |

36.2 |

|

37x1.5 |

0.8 |

1.0 |

2.0 |

2.0 |

37.1 |

|

41x1.5 |

0.8 |

1.0 |

2.0 |

2.1 |

39.5 |

IEC 60502-1

|

Conductor: |

class 2 (annealed plain copper) |

|

Insulation: |

PVC |

|

Inner & outer sheath: |

PVC |

|

Identification of core: |

numbering printing on white / black insulation, one is green-yellow. |

|

Armouring: |

Aluminium Wire Armour (AWA) Steel Wire Armour subject to availability |

ARMOURED AUXILLARY CABLES

|

Nominal cross sectional area of conductor a |

Thickness of insulation |

Thickness of inner sheath |

Nominal AWA diameter |

Thickness of outer sheath |

Approximate overall diameter |

|

No x mm2 |

mm |

mm |

mm |

mm |

mm |

|

48x1.5 |

0.8 |

1.2 |

2.0 |

2.1 |

41.4 |

|

7x2.5 |

0.8 |

1.0 |

2.0 |

1.8 |

24.4 |

|

10x2.5 |

0.8 |

1.0 |

2.0 |

1.8 |

29.0 |

|

12x2.5 |

0.8 |

1.0 |

2.0 |

1.8 |

29.6 . |

|

13x2.5 |

0.8 |

1.0 |

2.0 |

1.8 |

30.1 |

|

14x2.5 |

0.8 |

1.0 |

2.0 |

1.8 |

30.5 |

|

16x2.5 |

0.8 |

1.0 |

2.0 |

1.8 |

31.6 |

|

19x2.5 |

0.8 |

1.0 |

2.0 |

1.8 |

32.7 |

|

24x2.5 |

0.8 |

1.0 |

2.0 |

2.0 |

36.7 |

|

27x2.5 |

0.8 |

1.0 |

2.0 |

2.0 |

37.2 |

|

38x2.5 |

0.8 |

1.2 |

2.0 |

2.2 |

42.3 |

|

48x2.5 |

0.8 |

1.2 |

2.0 |

2.3 |

45.4 |

|

54x25 |

0.8 |

1.2 |

2.0 |

2.3 |

46.4 |

|

60x2.5 |

0.8 |

1.2 |

2.0 |

2.4 |

48.7 |

|

6 x 4.0 |

1.0 |

1.0 |

2.0 |

1.8 |

28.3 |

|

7 x 4.0 |

1.0 |

1.0 |

2.0 |

1.8 |

28.3 |

|

12 x 4.0 |

1.0 |

1.0 |

2.0 |

1.9 |

33.7 |

|

6 x 6.0 |

1.0 |

1.0 |

2.0 |

1.8 |

30.0 |

a circular stranded conductor (class 2)

Contact our sales team

Our sales team is available for support on size, specification and quotations, speak to our sales team for support on your cable requirements.